Electrical System Introduction¶

The electrical system of the GR-1 robot is designed to provide robust communication and power management across its various components. This system includes several key parts: the head, trunk, arms, lower limbs, power management module, and switch system. Each component is interconnected through an Ethernet bus and powered by a centralized 46V power supply, ensuring seamless operation and precise control required for advanced robotic tasks.

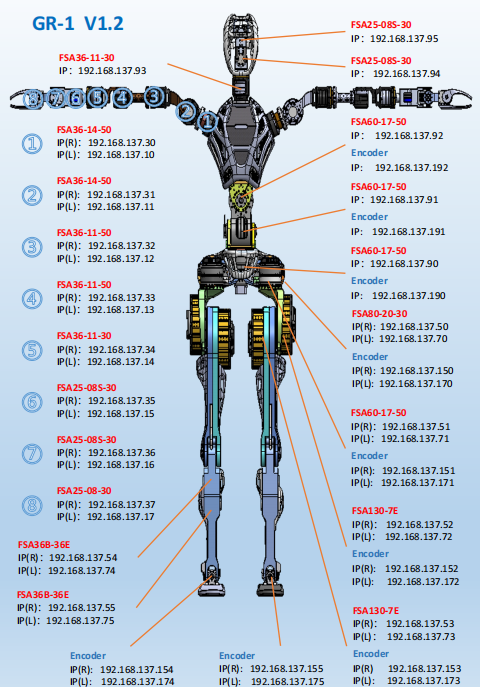

The IP configurations of each component is shown in the figure below:

Head¶

The robot neck is composed of three actuators, which communicate through Ethernet bus series connection. The power supply comes from the power management module, with a voltage of 46V. A depth camera is installed on the head and communicates with the main controller through a USB-Type-C cable.

Trunk¶

Both arms of the GR-1 are mainly composed of seven actuators on each side and a pair of dexterous hands, and each actuator is connected in series using Ethernet+46V power supply. The end of the arm communicates with the dexterous hand through Ethernet conversion to RS485 communication.

Arm¶

The GR-1 trunk consists of a power management module, a switch, and a main motion control unit. All Ethernet communication is eventually gathered on the main motion control module on the switch board to control all actuators. The buttons mainly include controller button, emergency stop button, and power switch button, which are respectively connected to the power management module for control. A 46.2V lithium battery is included in the back of the trunk and is charged by a matching DC charger.

Lower Limbs¶

GR-1 has 3 actuators at the waist, which are connected in series with the right leg;and each leg consists of 6 actuators. Each actuator is connected in series through a 46V power cable and an Ethernet cable. We are equipped with an end absolute encoder for position detection at every active joint in the legs.

Power Management Module¶

GR1’s power management module has many interfaces, including emergency stop button interface, start stop button interface, and battery charger interface. Our lithium battery pack is connected to the power management module. MCU can control the power supply of the entire actuator by controlling the on-off of solid-state relays. The power management module has voltage detection and current control functions.

In addition, the power management module also integrates a power supply interface for the motion control module, a breathing light control interface, a cooling fan control interface and a USB serial debugging interface.

The module itself also has Ethernet communication function. Through the Ethernet cable bus, it can be connected to the local area network of our entire robot, and the upper computer software can read the status information of the power management module in real-time.

Switch System¶

The switch module has 8 standard Gigabit Ethernet interfaces. The controller sends motion control commands to each actuator through these interfaces.